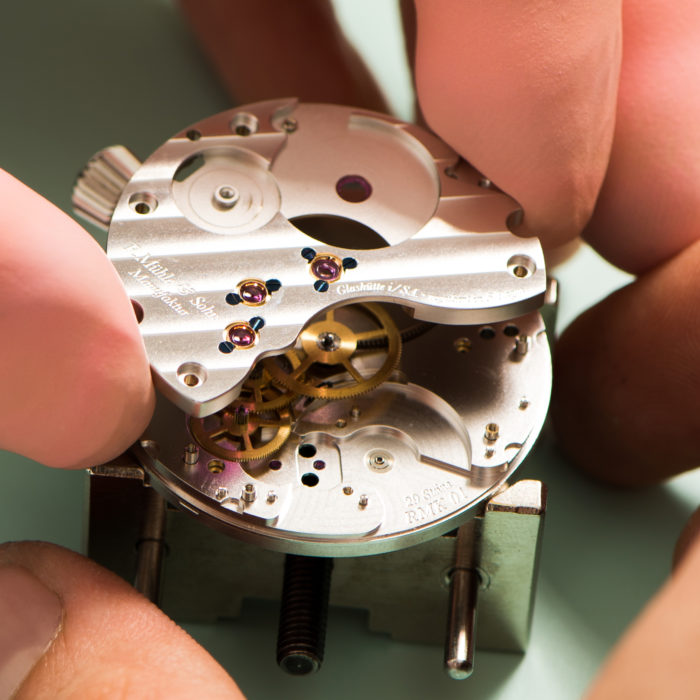

For a watch to function reliably and precisely for a long time, all components of the movement must work together perfectly: from the drive to the gear train to the adjustment. That is why we have not only developed our own fine adjustment, we also pay the utmost attention to the rotor.

The Mühle rotor provides the drive for our automatic watches. Set in motion by the wearer’s arm movements, it uses its rotation to wind the watch. To ensure that this happens efficiently, we manufacture it according to our designs on our own CNC machining centers. Because even here, everything has to be just right and manufactured to the tightest tolerances. Our rotor consists of the engraved center segment and a special heavy metal semi-tire that reinforces the rotor’s ability to rotate downward due to the earth’s gravity.

This flywheel is riveted to the outer circumference of the center segment with four or five gold-colored rivets. In its center we press a low-friction ball bearing, since the bearing of the rotor is particularly stressed by the constant movement. Finally, the rotor is nickel-plated or rhodium-plated, i.e. coated with an extremely thin layer of an element from the platinum group of metals. This gives it its shiny silver insensitive surface.